Solutions

The product range of Reis Robotics includes linear robots, gantry robots and the own robot control ROBOTstar.

In addition, there are the product areas of trimming presses, gravity die casting machines as well as the modular production cells and the manufacturer-independent integration of AMR (automated mobile robot).

For the complete systems in the areas of welding and cutting, foundry technology as well as handling and process technology, there is a wide range of standardized automation components in the company’s own product range.

Robot

Reis ROBOTstar

The iconic Reis ROBOTStar VI robot controller operated via the familiar reisPAD has set standards in terms of path following accuracy for cutting, welding and positioning applications, simplicity & intuitive use, and ability to control more than 18 axes.

The graphic ProVis graphical visualisation and TouchMotion control enable simple and application-related operation and programming of the robot. The fully integrated SafetyController as well as the freely programmable safety PLC serve to protect people and save an external PLC for smaller applications. Open communication standards enable seamless integration into production systems. Upgrades for existing systems are also possible at any time. Please contact the Reis service department.

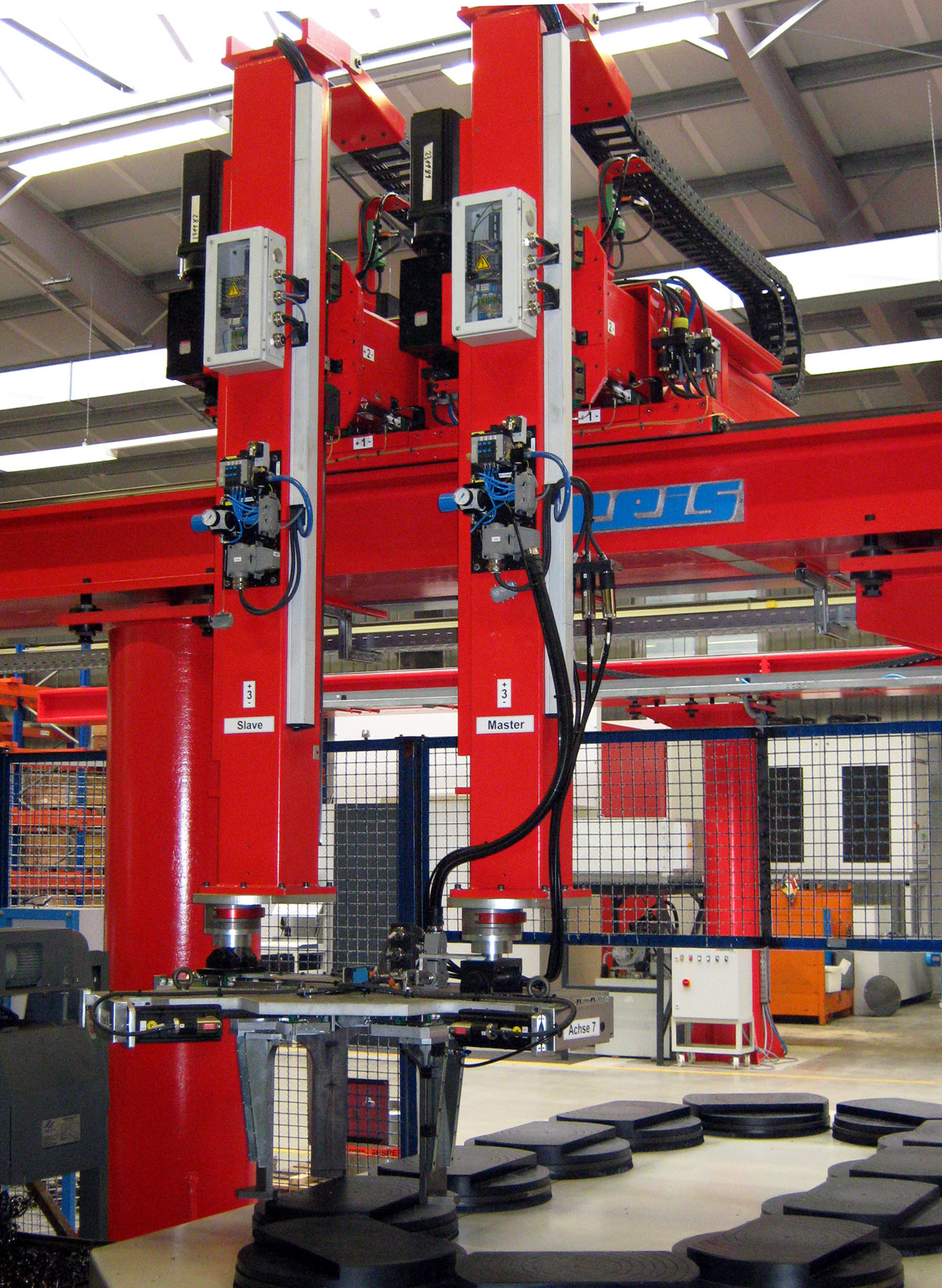

Linear- and Gantry robots

Reis Robotics offers a broad portfolio of linear and gantry robots. The main field of application of these systems is the interlinking of workflows between machines and processing systems, such as automatic loading and unloading, turning and repositioning, production and casting systems. All machines can be flexibly adapted to customer-specific system solutions in terms of stroke lengths as well as through optional expansion with additional rotary axes and various gripping devices.

Positioner

A whole range of peripheral modules in various designs is available for the provision of workpieces, such as the rotating and tilting modules, which enable a component to be rotated. In addition, we also develop peripheral modules for changing workstations:

- Turntables

- Rotary turning positioners

- Indexing tables for setting up several stations

Foundry machines

GIGA Casting

Die-casting machines with higher clamping forces offer new solutions for the automotive industry. Giga- or megacasting enable the production of structural components with increased functional integration and large dimensions. We will be happy to advise you with our know-how and products and work out an optimal deburring solution for your application – traditionally using large deburring presses or innovatively using laser technology.

Trimming presses

The entire series, with over 30 different sizes and models, in 3 or 4 columns, offers optimal solutions for manual or automatic operation. The presses are characterized above all by their speed, precision, and durability.

The customer receives special advantages thanks to low-backlash column guides and bending-resistant press frames that guarantee precise cutting. The deburring and machining of different planes in a single clamping ensures high economic efficiency and profitability.

Casting Machine

The innovative drive, operation, and control concept of the reis robotics gravity casting machines offers you best conditions for an optimal casting quality. The gravity casting machines are available in different versions both as single and double tilting casting machines. All versions convince with the same advantages and can be used flexibly and efficiently in your production:

- Robust and torsion-resistant mechanics

- Innovative, low-play drive concept

- Exact positioning through servo drive

- Also suitable for linear casting cells and casting turntables

- Interface for media system available (e.g. gas or cooling)

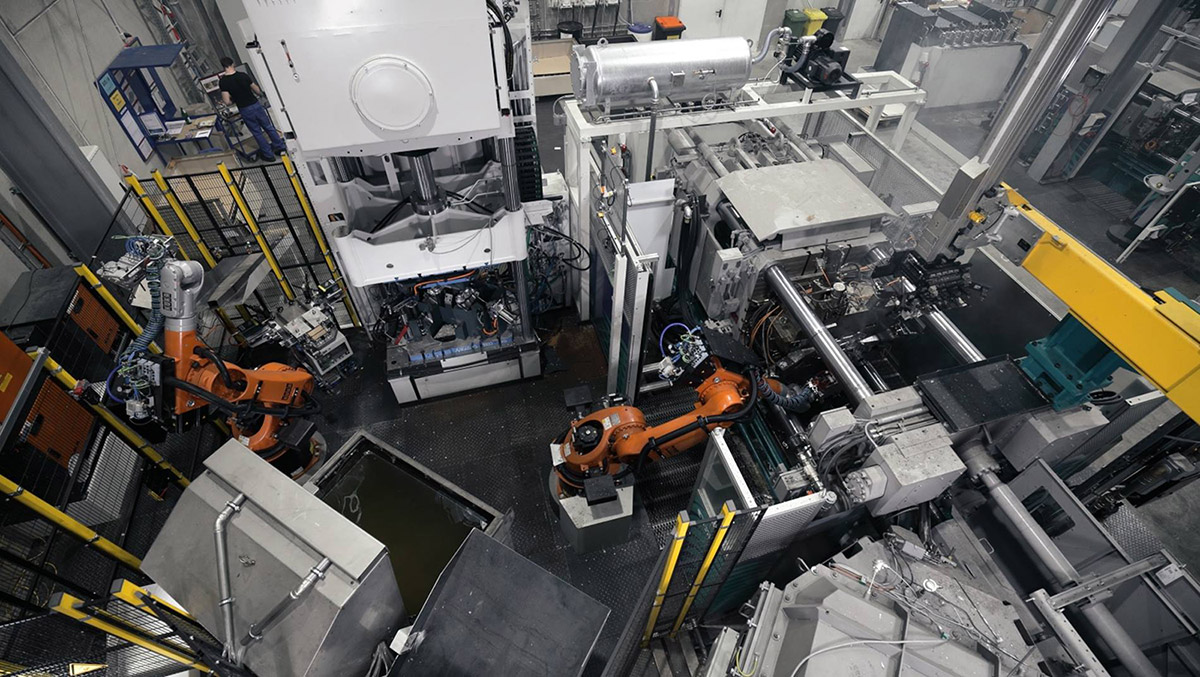

AMR Integration

Discover the future of industrial automation with our AGVs and AMRs. A wide range of AGVs and AMRs from KUKA and other third-party vehicles can be connected to the intelligent fleet software. Our solutions enable seamless integration into your existing systems and utilize advanced IIoT technologies. The AGVs and AMRs are VDA5050 compliant and can be easily integrated into your production. Optimize your production processes and let us automate your intralogistics together.

Production cell portfolio

Whether welding, lasering, fettling and deburring – our modular production cells offer high quality and performance at an attractive price. In addition to our application expertise and perfectly matched components, our cell portfolio is flexible to use, preconfigured, quickly integrated into production environments and easily scalable.