Our industry applications

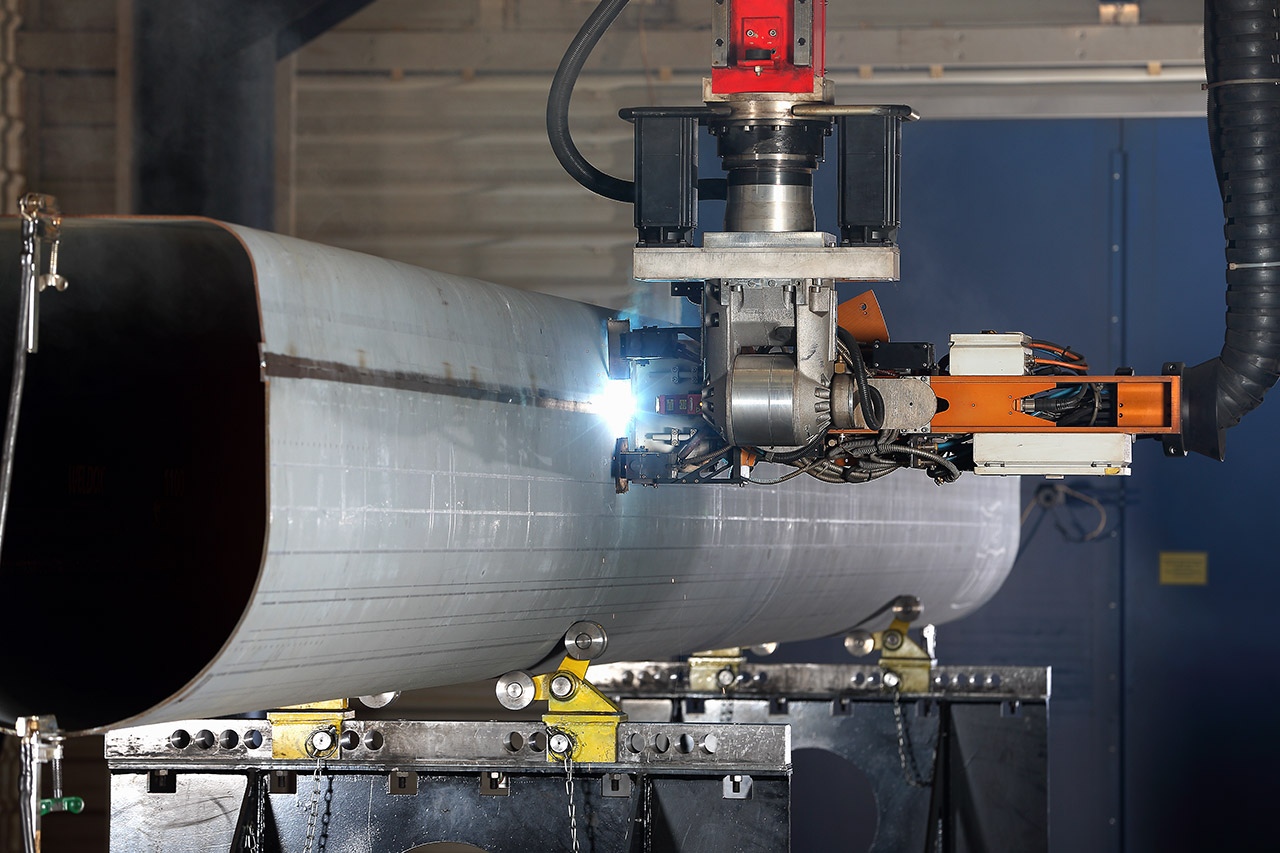

Metal Industry

Industrial automation solutions for the agricultural and construction machinery industry as well as for the metal construction and contract manufacturing industry - customized and individually designed. Our team offers comprehensive and professional advice as well as high quality of service for your requirements. Our Welding & Cutting portfolio offers application expertise in a wide range of welding and cutting processes as well as software, sensor technology and safety technology, tailored to your specific needs.

Foundry Industry

Our decades of experience in the foundry is reflected in our broad portfolio. With more than 16 different models of our trimming presses, the new GIGA Casting trimming presses, and the intelligent Dialog IV control system, we can realise modular, fully automatic cell concepts through perfectly matched components for flexible die casting cells or gravity die casting lines. We also offer solutions for processing sectors such as sawing, deburring, grinding or drilling, both as standardised, transportable cells and as modular cells or line concepts.

Food Industry

Our focus is on the efficient and precise handling of primary and secondary products in the food industry. We specialise in the development of pick and place applications that can be seamlessly integrated into ongoing production processes. Whether it is meat, cheese or other food products - we take on the task of picking your products safely. In doing so, we master both simple and complex picking applications that can be performed by multiple robots simultaneously. Our expertise in palletising and depalletising, as well as the seamless integration of AGV and AMR fleets, opens up completely new possibilities for automated picking of food products.

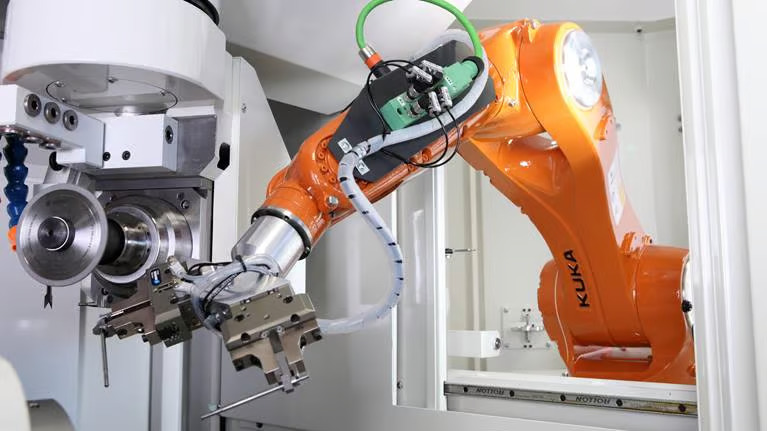

Loading and unloading of machines

The loading and unloading of machines and special machine tools is a key area in which we have been successfully active for many years. Using articulated arm and linear robots, we can customise your automation and integrate it into our partner model or rely on our proven modular cell portfolio. The integration of component recognition and labeling, camera-based DMC reading, component blow off and cleaning and quality inspection are all part of our portfolio.

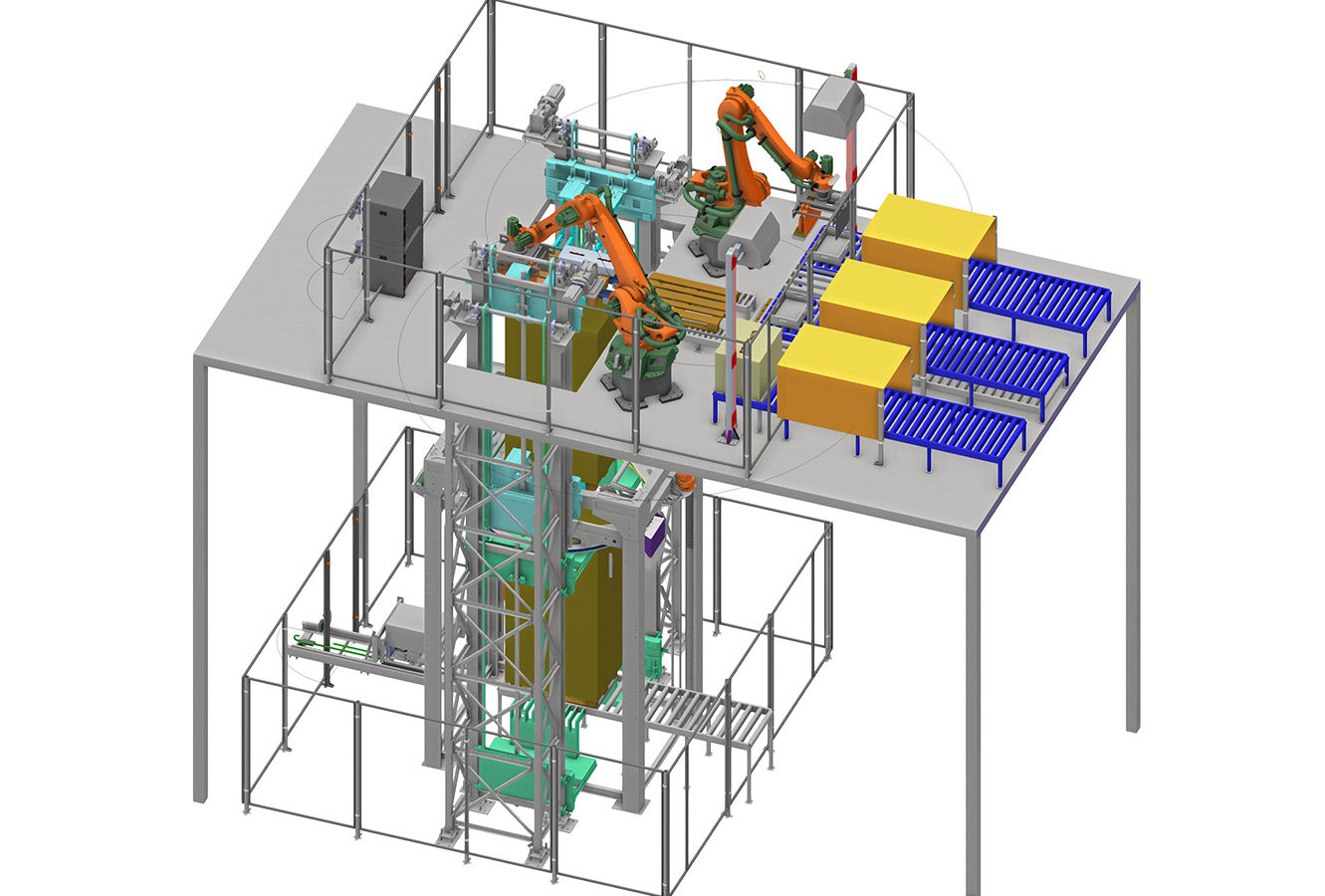

Mixed Palletizing

Mixed palletizing enables efficient palletizing of mixed products that are stabilized and protected by stretch wrapping. The advantages of this system include software-controlled patterning, simultaneous palletizing and stretching, an integrated wrapper with automatic film change, and the addition of a top layer. In addition, it allows handling of different product sizes and the combination of vacuum and clamp gripping systems. With an impressive cycle time of just 4 seconds per package, mixed palletizing is particularly effective in the field.

3D-Printing Robot cells

Robotic 3D printing is becoming increasingly important in the manufacturing industry. Unlike traditional 3D printers, robots enable a larger workspace and faster production of parts. With our experience in robotic extrusion and laser additive manufacturing, we support you from design and material evaluation to feasibility studies, manufacturing, delivery and commissioning of our robotic 3D printing solutions.