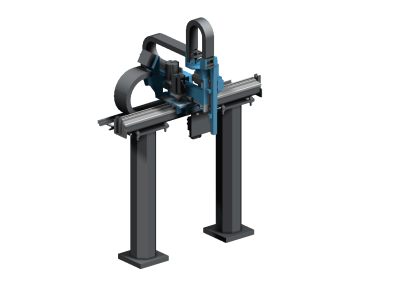

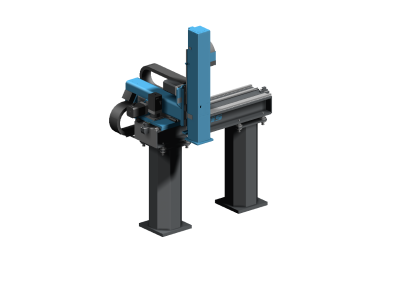

Linear Robots

Linear robots usually consist of three linear axes (X, Y and Z), which are arranged orthogonally to each other. Internally at Reis Robotics and in the corresponding documentation and programs, these axes are referred to as A1, A2 and A3. Each of these axes moves along a straight line and is driven by AC servomotors over a gearbox, whereby the power is transmitted via a rack and pinion drive.

Additional axes can be integrated into all linear robots, in particular additional rotary axes, which enable additional degrees of freedom and orientation options in one or more directions. This makes it possible to carry out even complex tasks. Due to the high accuracy of the additional axes and the robots as well as the various degrees of freedom, even demanding process tasks such as welding can be carried out precisely.

The linear robots are usually mounted on columns, leaving the working area, which can be a maximum of 45 meters in one direction due to the A1 axis alone, completely free for applications and various components except for the column mounting.

Advantages:

Large work area

With a cubic workspace size of up to 45 meters in axis A1 and up to 2 meters in axis A2, our linear robots offer an impressive amount of work space for a wide range of applications.

Combination of linear and rotary movements

Our linear robot optionally combines linear and rotary movements, enabling it to perform complex assembly and machining tasks with improved performance and accuracy.

Optimum space utilization

Thanks to the optional additional rotary axes, the robot can perform tasks more efficiently in limited spaces, which is particularly important in environments with limited space.

Optimized positioning

The optional additional rotary axes enable the robot to bring the gripper / end effector workpiece into optimum positions, which increases the processing speed and product quality.

Speed and efficiency

The integration of additional rotary axes enables faster and more efficient handling of processes, resulting in shorter production times and lower costs.

Precision and repeat accuracy

Our linear robots offer exceptional precision and repeatability, which are essential for demanding applications.

High speed

Thanks to their linear movement ability, our linear robots can reach high speeds, which enables efficient execution of tasks and increased production output.

Flexible positioning

The linear structure allows our robots to move flexibly and precisely even over long distances, enabling versatile positioning and handling of workpieces.

Safety

Our robots can be equipped with modern safety systems to make interaction with personnel safer and prevent accidents at work.

Adaptability

Depending on the application, our linear robots can be configured to handle different workloads and sizes, increasing their versatility and adaptability.

Efficient space utilization

Compared to other types of robots, linear robots often take up less space, especially on the shop floor, and can therefore be used in space-restricted production environments or small work areas.

Robustness and reliability

With high-quality components and a robust design, our linear robots are designed for reliable continuous operation in demanding production environments.